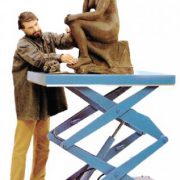

The “lifting table” is a fixed lifting device, hydraulically operating. It is shaped to bear evenly or partially distributed loads as well as concentrated and on the move, e.g forklifts. It is made of an upper frame, a lower frame and a scissor system, which works thanks to one or more cylinders.

The upper frame is realized with a covering of smooth or diamond plate; it accomplishes a vertical movement, parallel to the floor. The scissor is hinged at one edge of the upper and lower frames. The other edge of the scissor runs on wheels in suitable horizontal rails obtained into the upper and in the lower frames.