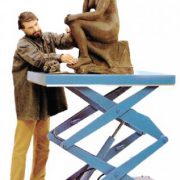

What is a lifting table? Simply, it is an hydraulic table, which raises and lowers at a required height; specifically designed according to the customer needs, with a wide range of possibilities to lift loads, having various stroke/excursion and dimensions. It follows that there are many application fields, among which the logistics, the connection between two floors, production lines, automatic systems inter-locking, car-lift, up to more specific and particular applications: we space from the lowering of the coffins at the morgue to raising dancer of the classical Ballet or theater sets.

The lifting tables task in the industrial production

Nevertheless, the real aim of a lifting table is to avoid bending efforts and prevent predictable accidents, caused by improper movements and body poses or still wrong handling of heavy loads.

Latest EU reports on Health and Safety highlight how the loss of more than half of the working days is due to health problems connected to the work, which involves also injuries to muscles, bones or connective tissues, all known as musculoskeletal disorders. These disorders represent the main challenge for Europe, speaking about health and safety. Beyond 40 million workers suffer in Europe of such diseases. These traumas, due to improper work position or inappropriate lifting of loads, accidents excluded, cost more than 385 million Euros, between 0.5% and 2% of European PNL, a significant data for the European economy.

Companies spend time and economic resources on prevention against accidents at work: these investments are not always effective, above all for what concerns the prevention of musculoskeletal injuries. Such injuries are often caused by contingent and not always traumatic factors, like repetitive movements, incorrect postures, poor lighting that leads to unnatural movements, raise of loads not always heavy, but wrongly managed.

In many of these cases, to introduce a lifting table helps not only to reduce such injuries, but also to increase the productivity.

Ask Armo for an analysis of the operations. We will put our 44 years-old experience in the lifting tables and loading point’s field at your firm disposal. A well-managed goods handling, together with the proper movements of the operator during the working phases, will decrease the costs resulting from the casualties and will increase the productivity and efficiency of the working cycle.

Listed below, there are some occupational issues that can be solved by introducing a lifting table; specifically designed for customer need:

Workers:

- They stay in the same position for too much time

- They absorb the vibrations of the tools

- They often move away from their workstation

- They modify, by mistake, their workstation and their tools

- Many people carry out the same activity at the same time

Other possible problems are:

- Difficult access to the remote controls and no easily readable

- Low lightness, ventilation and air conditioning

- High number of injuries and accidents at work

- Absences, disciplinary actions, damages on tools and frequent changes of staff in a specific working station

- High processing and waste of materials

- Low productivity, low quality of the product as well as alow performance, even with shift work

Armo will be glad to show you how to increase the profitability of your production, through the introduction of a lifting table in your working cycle, reducing also the injuries and the costs for their managing.

It can be said with certainty that decreasing the incidence of musculoskeletal injuries of its own staff, frees economic resources for the company, which increaseas its profitability.