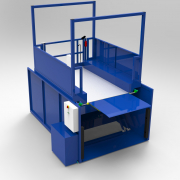

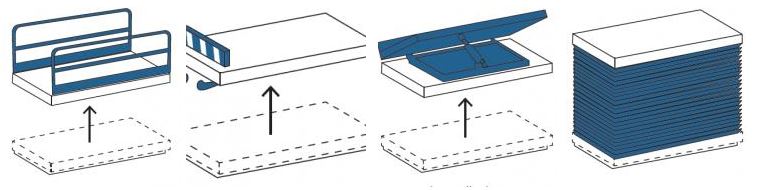

The “lifting table” is a fixed lifting device, hydraulically operating. It is shaped to bear evenly or partially distributed loads as well as concentrated and on the move, e.g forklifts. It is made of an upper frame, a lower frame and a scissor system, which works thanks to one or more cylinders.

The upper frame is realized with a covering of smooth or diamond plate; it accomplishes a vertical movement, parallel to the floor. The scissor is hinged at one edge of the upper and lower frames. The other edge of the scissor runs on wheels in suitable horizontal rails obtained into the upper and in the lower frames.

The lifting table is made of a single monoblock structure, equipped with suitable threaded hooks for its raising and installation. Special maintenance bars are provided to allow the subsistence of the lifting table.

The hydraulic power pack works thanks to one or more cylinders. On each cylinder, there are two safety valves: a limited device intervenes in case of a broken pipe, even if the lowering control is working. It allows the lifting table lowering at a controlled speed. A ball-sealed solenoid valve prevents oil leakage and guarantees the placement at the level. The hydraulic system on the platform, with inboard power pack version, is connected to the platform itself; with outboard and/or excluded version, it ends in a suitable union pipe welded on the lower frame.

The electrical system on the platform (including the up stroke and safety perimeter limit switch and the electrical-valves wires) for the inboard power pack version, is connected to the platform itself, in the outboard and/or excluded version, ends in a suitable shunt box, fixed on the lower frame.

In the end, there are several options available, which can complete Armo lifting table’s quotations. Feel free to contact us for a customized quotation.

You can find further details about our lifting tables, complete with technical features, dimensions and much more in the Products Menu.