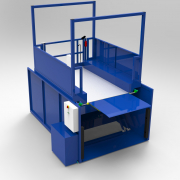

A great news is ready to change the lorry loading/unloading lifting tables market: the OMEGA table. Realized following the usual system of scissor, always safe and confident, the OMEGA table permits to load/unload truck by using a lifting table, without any pit requirement. On board controls are comfortable and the operator can quicken the pace, always in total safety. Change your old mobile yard ramp: install a modern and safe product as our OMEGA lifting table without any pit.

Reduced closed height (60 mm) permits to install the table directly on the ground, without any pit realization, to load without any difficulty pallets up to 2500 kg. on the upper frame thanks to a useful inviting chute.

The rear gate, supplied with a safe electrolock and lateral protections make the work easy and safe. Frontally, a hydraulic tail of 1100 mm depth helps against the fall when it is in its rest position and permits as well to reach all trucks in order to transfer goods. Frontal photocells protect from crushing risks during the loading phases.

Rubber buffers (when required), outside treatments, special dimensions: those are all accessorizes and options, which by request can personalize your OMEGA scissor table without any pit, for loading/unloading trucks.

We remind that all our tables (so the OMEGA as well) are checked in our warehouse before the departure; they are ready to be easily installed unmistakably. Ask for a free quotation and you will be astonished of how easy can be solving one of the most common problems: to load/unload trucks or vans when there is no way to make a pit and without employing the nowadays old, unattractive and cumbersome mobile ramps.

Scissor lift table in closed position